Guild technical director Steven Howard explains rear outlet flue connections.

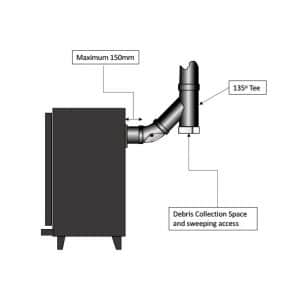

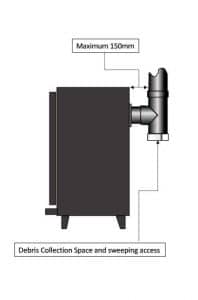

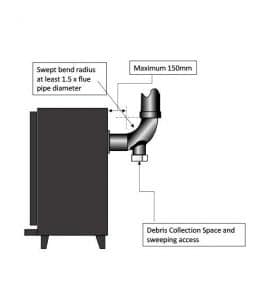

Following numerous discussions and feedback from chimney sweeps relating to the use of 45-degree bends off the rear of an appliance, here I can hopefully explain things more clearly. The three diagrams here show acceptable ways to make bends from the rear of an appliance.

There have been many questions raised as to whether it is acceptable to use 2 x 45-degree bends off the rear of an appliance instead of a 90-degree T piece.

BSEN 15287-1 with its generic principles and taking into account best practice considerations means the installation should be both safe and avoid any blockages within the flue pipe. In the absence of any industry data relating to issues with blockages when using 2 x 45-degree bends, the interpretation of BSEN 15287-1 and Approved Document J is quite clear that a debris collection point is required.

I am aware that some manufacturers currently make a 45-degree rear connection component, or a rear outlet flue box which has been interpreted as a common approach where there is restrictive space at the rear of the appliance. It can be noted however in some instances this manufactured component connection is slightly lower than the appliance spigot outlet, thus allowing for some debris collection within this area.

The new BS 8303: 2018 outlines the following:-

The horizontal exit of the appliance shall be connected to a vertical connecting flue pipe using either: a T-piece connector with the bottom of the T-piece connector forming a debris collection trap and allowing for sweeping access, or, a swept 90-degree bend incorporating a debris collection trap, with the swept bend radius being 1.5 times the connecting flue pipe diameter. (Sweeping access must again be provided as this is effectively 2 bends). The maximum horizontal length of fluepipe remains 150mm. However, BSEN 15287-1 gives an alternative approach that permits an extended length of horizontal section of flue pipe (max 450mm) when a number of specific requirements are met, namely the requirements of BSEN:13384-1. What this basically eludes to is that a calculation carried out shows sufficient draw and the flue gas velocity and temperature are achievable, meeting both the chimney and appliance manufactures requirements.

In all instances, suitable access distance should be provided around the appliance to enable safe removal of the products of combustion, and distances to combustible materials must also be maintained.