You can download / print this document HERE.

If you work in the solid fuel industry you need to know what happens when wood burns. More importantly you need to know what happens when it’s not burned hot enough. You can save your customers money, keep them safer and make a big difference to air quality.

The information here compliments the consumer awareness information at www.burnright.co.uk and in the printed brochure – “We all breathe the same air” Chimney sweeps in particular have a unique opportunity to deliver the right information to their customers.

Wood as Fuel

Wood is an excellent fuel. It is plentiful, and renewable. It is often sourced close to the point of use. At a basic level it requires little processing – just cutting and splitting. It can be used to manufacture other wood based fuels. The use of wood as fuel however is not well understood. Consumers are often unaware of how to get the best from their wood fires / stoves. Most people think they know how to burn a few logs but there are several important factors which are often overlooked and this causes problems.

The problem in stoves / woodburner

The basic problem is that the wood is often not burned in an efficient way. That is to say it is not burned hot enough. Most of what is burning when using wood logs are “volatile hydrocarbons”. These are things like tars, creosote and resins etc. They constitute about 70 – 80% of the available heat energy in any log. When we see flames coming from wood, it’s the volatile gasses that are burning.

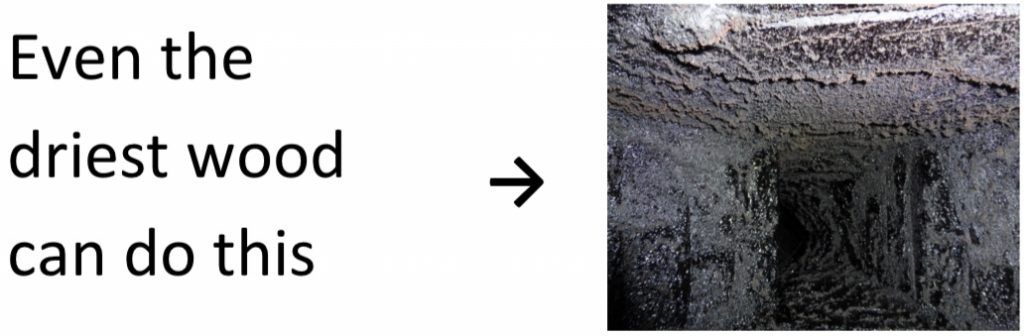

Most of the rest of the available energy is fixed carbon (charcoal) at around 15 – 18 %. When we see wood and embers glowing, it is the charcoal that is burning. If the stove is not hot enough it’s the volatile tars etc. that cause a problem. These volatiles must first be turned in to a gas (vapourised) before they can burn. If the fire is not hot enough the volatile vapours are still given off but they are not completely burned in the appliance and they escape to the chimney. If the chimney is cool enough, some of these tars will condense and solidify on to the inside of the chimney in the same way that water vapour condenses on to a cool bathroom mirror. In a cool chimney they can immediately solidify to form the tarry deposits or creosote glaze.

Of course, not all the tarry vapours solidify inside the chimney. A great deal is emitted from the top as un-burnt hydrocarbon or smoke. Smoke is simply unburned fuel. This is a serious air pollutant. Much of the available fuel which could have been turned into heat has also been lost. Incomplete or low temperature burning of wood is bad for your chimney, bad for air quality and bad for your wallet.

How do you know if wood is burning efficiently?

There are four basic factors which govern efficient combustion of wood. These factors directly affect the temperature inside the stove, which in turn governs efficiency / pollution etc.

- User operation / control of the stove – this is usually the most important but most misunderstood factor.

- The moisture content of the wood

- The efficiency of the stove

- The efficiency / construction of the chimney

The size of the stove is also important. If the kW (heat) output is too much for the room then this will be an additional problem. Low temperature burning is likely as the room soon gets too hot and the operator closes the air controls off too much.

1. User operation and control of the stove

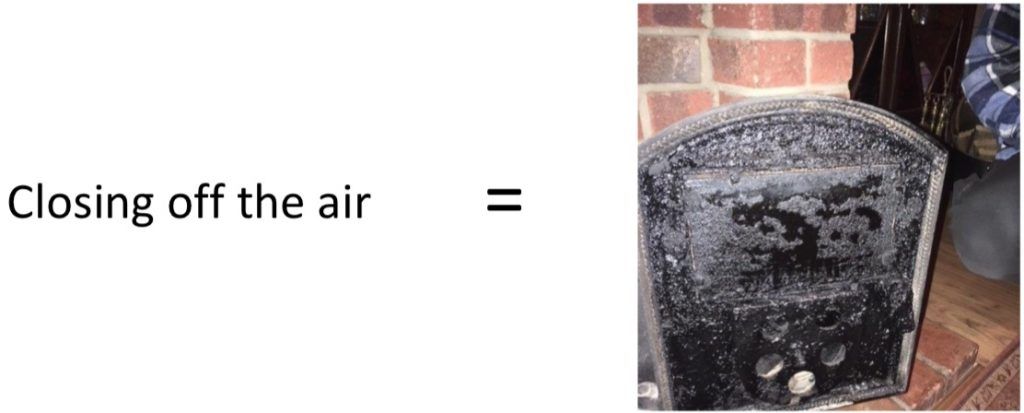

Here is something worth remembering: You can take the driest wood, burn it in a good stove with a good chimney but if the air controls are closed off too much then the temperature drops, large amounts of fuel are wasted and lots of unnecessary pollution is caused.

Closing the air controls too much is the greatest cause of unnecessary air pollution and “tarry” chimneys. There is a real lack of consumer awareness regarding the correct operation of the air controls on stoves.

Manufacturer’s instructions on operation may be missing, forgotten or just ignored. Often the user just makes up their own mind as to what’s best. But, it’s all about the temperatureof the burn. If the air controls are shut down too much, the burning temperature drops and vapourised fuel escapes to the chimney. Following manufacturer’s instructions on burning and operation is good but a basic understanding of what is going on helps users get it right.

2. The moisture content of the wood

The moisture content of wood is a key factor for efficient burning. Any water in the wood must be “boiled off”. This requires an input of heat energy which is then lost to the chimney as steam. Wood for burning should be around 20% moisture, 15% even better.

If the wood is too wet, the temperature in the stove can’t get high enough to achieve efficient combustion and un-burnt fuel vapours enter the chimney. To make things worse there is more water vapour in the smoke. This can cool inside the chimney to condense and solidify to shiny “tar or creosote”. The emission of unburned tars, creosote etc. is increased if burning wet wood, as is the chance of a chimney fire. Burning wet wood and smokeless creates more pollution and wastes money. What’s more, the increase in water vapour helps form acids which will etch the stove glass and corrode metal parts of the stove and chimney. Not good.

3. The efficiency of the stove

If the stove is well designed and built, it should be capable of burning efficiently. But many stoves already installed in the UK are capable of having the air controls closed down too much by the user. Many well regarded makes of stove are easily turned in to inefficient and polluting appliances. If the same stoves are burned hot enough, the problem is greatly reduced.

If the stove is too large for the room the operator is likely to burn small, cooler fires which give the same problem.

More efficient stoves are designed to capture and burn almost all the fuel. They are designed so that the operator can’t shut down the air to the point where combustion is restricted. This type of stove won’t work with wet logs. They are the future. In the meantime it is consumer awareness and education that can make all the difference.

4. Chimney efficiency

Even a very efficient and clean burning stove will not reach its potential without the right chimney above it. Most people find it difficult to think of a chimney as being “efficient” but it is a key part of the system. It must exert an appropriate and consistent draw / pull to power the stove. To achieve this it must be high enough. It must be the right size (cross section) and be well insulated. The top of the chimney must terminate in the right place – free from turbulent and disturbed air. Lastly, the pot / cowl / terminal should not impede the exit of combustion gasses.

Getting it right

You can find excellent consumer video guides on “getting it right” at www.burnright.co.uk The guide is also available as a printed brochure.

Most solid fuel professionals will already know and use the information below but it is always useful to have a general guide to help your customers. Please re-use the information below as you wish.

Getting it right

Lighting and getting up to temperature.

A reasonable load of appropriate fuel should be placed in the stove along with any firelighters. Light the fuel, close the door and make sure all air controls are fully open. Follow the manufacturer’s instructions but as a basic guide a 15 to 20 minute burn will bring the stove up to correct operating temperature. Try to maintain a moderate flaming combustion. If your stove is designed to pre-heat the combustion air, it is even more important to get it up to operating temperature. If it does not reach this temperature before you begin to close controls, the combustion will not be so complete, un-burned fuel vapours will escape to the chimney, wasting fuel and causing pollution.

After 20 minutes or so, once the optimum operating temperature is reached you will probably need to re-fuel. Let the fuel start to burn before beginning to close any air controls. If your stove has more than one control it may able to pre-heat the combustion air. Now is the time to completely shut the control which allows the room temperature air in. You can then begin to set the rate of burn with the pre-heated air control. Don’t shut it too much! You have a box full of hot burning fuel and if the air is reduced too much, combustion is incomplete and you’ll be losing fuel to the chimney again.

Smoke (un-burnt fuel) should only issue from the top when you first light or are re-fueling the stove. If smoke is present at other times it’s usually because the fuel is not burning hot enough. This is usually because the air controls are closed off too much. It’s a good idea to go outside and have a look at the top of your chimney when the stove is properly up to temperature and the wood is burning nicely. You should see no smoke. Return to the stove and shut the controls, go back outside and have another look at the top. You should now see lots of smoke. There will be a point beyond which you should never close the air controls. A little experimentation and you should be able to find this quite easily. Efficient stoves have been designed to prevent the user from closing the air down beyond a certain point. They also introduce high temperature pre-heated combustion air in a turbulent manner and hold the fuel / air mix in the combustion box for longer.

Your local professional chimney sweep will take you through the process for your stove. If they can’t do this or don’t think it’s important then perhaps change your chimney sweep!

The design features of very efficient stoves ensure that the burn occurs at optimum temperature most of the time, so there is very little escape of un-burnt volatile fuel to the chimney. If there is no un-burnt fuel inside the chimney, there can never be a problem with tar / creosote build-up. Choose your stove carefully.

Overnight burning / slumbering for long periods

Don’t do this. It’s a bad idea to fill up a stove with fuel and shut the air controls right down. This practice is becoming less common as professional sweeps help educate their customers.

“Slumbering” the wood is very bad practice and more than half the available fuel load may be lost to the chimney. In an average size stove this could easily mean that over a kilo of vaporised fuel gasses are lost every time! Here is what happens and again, it is all about the temperature of the burn:

When the air supply to a stove full of burning wood is closed down, the volatile fuel gasses are still being given off. The temperature inside the stove immediately drops. Fuel gasses escape to the chimney, tarring it up and causing un-necessary air pollution. Once all these volatile fuel compounds have been driven out of the wood you may be left with some pure carbon – charcoal. This will then burn at whatever rate the available oxygen allows and the process can take a long time. Burning an identical load of wood faster and at a reasonable temperature will significantly reduce or eliminate the loss of fuel to the chimney. If you are in the habit of burning at night, then set your air controls so that no smoke is coming from the chimney top. You are now burning much more fuel in the stove rather than letting it

Closing off the air

escape to the chimney. The stove will deliver much more heat to the building but over a shorter period of time.

Some stoves are made with large slabs of stone etc. The stone captures heat and releases it slowly back to the room long after the fire has gone out.

Size of Logs

The size of your logs will make a difference to how they burn. The greater the surface area of the wood relative to its volume, the faster the tars etc. can be vaporised and burn. 5 to 6 inches wide is best.

Storing / drying your wood

You can easily dry your logs down to 20% moisture with correct storage. Stack logs so the air can get at them. If you cut and split them yourself try to do this when the wood is fresh cut as it is much easier on you and your tools. Once split, you have greatly increased the surface area of each piece and it will dry much faster. A well ventilated log store with open sides and a roof on it is the best situation. Dry your logs to a moisture content of 20% or less. Time taken to dry will depend on a number of factors – ventilation, type of wood, size of logs, average local humidity, sunshine etc. There are some good books on the subject – “Norwegian Wood” by Lars Mytting is one of the best. A moisture meter is a very useful tool. To test the moisture content of any log, split it first and then test the split surface.

Beware of the word seasoned, it means nothing in reality. The only important consideration is the moisture content, not how long it has been cut or stored.

The BurnRight website has a “Trade Information” page. The page is password protected to separate it from the consumer information. The password is burnright. This page has a video presentation explaining the causes of poor air quality with regard to domestic combustion. It also highlights the tools available to help sweeps etc. alter consumer habits and gives guidance on how to use them.

BurnRight is a national consumer awareness campaign which seeks to address the issue of domestic combustion and unnecessary air pollution. It is particularly concerned with the issues concerning woodburning stoves.

The campaign is spearheaded by professional chimney sweeps. Chimney sweeps have unique insight into the causes and solutions regarding this problem. They understand the relationships between the appliance, the fuel and the way the consumer operates their stove. They have the knowledge and the opportunity to make a positive difference to most consumers burning habits. With BurnRight they now have the tools to help them deliver the right messages.