Lots of our customers use wood briquettes, but do you know what goes into them and what makes a good briquette? David Ousby explains:

Feedstock

The process of manufacturing briquettes requires consistent quality of feedstock, often from the waste arising from wood processing activities. Any contamination in the feedstock will be concentrated during the process, often to the extent where the contamination presents itself as an obvious visual defect in the briquette. Feedstock can arise from a range of processes, from timber mills (where excessive moisture from unseasoned wood can be an issue) through to joinery workshops (where contamination from composites e.g. MDF, plywood etc. can occur). For this reason, the production of good quality briquettes needs to have quality control measures in place that control the quality of the feedstock, ensuring only sufficiently seasoned clean wood is used. The feedstock needs to be reduced in size into woodchips of 10mm or less, often using a slow single shaft shredder. The shredding process will result in a feedstock mix of dust and particles, the mix being further refined if need be, to create the optimum blend of woodchip and dust.

Density

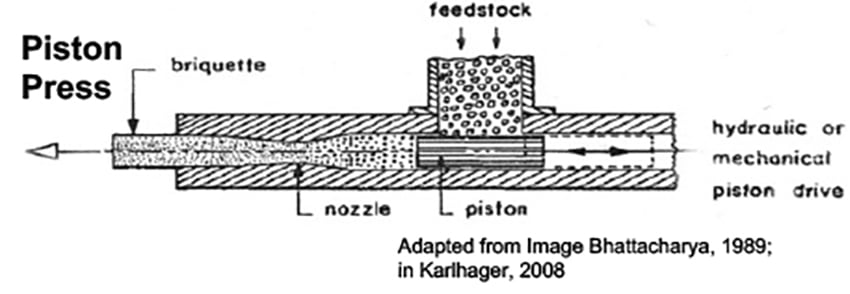

Briquettes are made from wood that has been shredded and then compressed in a briquetting press, typically at around 100psi (1,000Kg/cm2). At this kind of pressure, the lignin in the cells walls of the wood fibres heats up and melts, becoming a kind of natural glue that sticks the wood dust and particles together. The physical bonding of the lignin due to Van De Vall’s forces, where the moisture in the material creates a chemical bond, drawing the particles together, with the pressure then creating the physical bond.

The pressure is formed by a massive hydraulic ram pushing a piston into a closed cylinder of wood chips and dust against a solid mass of briquette, itself held in place by a hydraulic vice. The process to make the briquette takes just a few seconds at 100psi, after which the vice automatically opens, and the cycle begins again, with the ram being withdrawn and the cylinder being automatically recharged with another load of wood chip and dust from a container holding the feedstock.

Heat

This bonding creates a briquette with a density typically of 1.01 or above – drop them in water and they will sink. Kiln dried hardwoods will have a density of 0.5 at best, therefore the briquettes have twice as much heat density when compared to firewood. The heat output from a briquette is typically 4.5kWh, which is similar to the best quality seasoned hardwood logs. This is enough fuel for a 4.5 kWh stove for one hour, but because of the heat density, the briquette will require less space inside the stove. For this reason, customers are advised not use too many briquettes when fuelling, as they will typically put out twice the amount of heat that the same volume of seasoned firewood can deliver. Due to their high heat density briquettes perform much better than seasoned hardwood where a stove is consistently required to deliver its maximum heat output, for example during very cold weather.

Moisture

The feedstock that goes into briquettes needs to be fully seasoned with a moisture content of between 6-14% wmv. Some moisture is needed to enable the chemical bonding that takes place due to the Van Der Vall’s forces. Too much moisture will result in steam being formed under pressure in the vice, which will escape from the briquette after it has left the vice, causing the briquette to expand and disintegrate. For this reason, briquettes will always have a lower moisture content than firewood and need to be kept in airtight packaging to prevent them absorbing moisture from the atmosphere, especially if they are stored outdoors. If exposed to excessive moisture in storage, they will absorb the moisture, expand, and disintegrate. In storage, briquettes will take up less space than seasoned hardwood logs, due to their density, and can be kept outdoors, for example in a log store, if they are in airtight packaging and not exposed to the worst of the elements.

Ash

The ash content of briquettes can vary, depending on the amount of stem wood to bark used. If no bark is used the ash content would typically be 0.8% or less, meaning the grate will not need to be cleared out as often, and there is likely to be less ash build up (if any) in the flue. Due to the low moisture content, combustion is more complete, provided the burning temperature is high enough. There is less unnecessary pollution and ash than would be the case if unseasoned firewood / excessive bark is used. The typically lower ash content is especially advantageous during periods of severely cold weather, where the down time of the stove required for removing ash is reduced.

Common issues

For some customers, the higher heat output from briquettes can result in discomfort. This can be mitigated by using less fuel and getting into the habit of fuelling the correct amount of fuel more regularly.

Some customers find it inconvenient to keep having to refuel their stove every hour or so, especially in milder weather when a woodstove is used for background heat. This can be remedied by fuelling the stove little and often, or not at all if it is not cold enough to keep the stove fired efficiently.

See video of making briquettes:

https://www.youtube.com/watch?v=guDDpAopEig

NB. The company featured is no longer trading.